In the textile and apparel industry, calendering finish and coating finish are common methods used to Sleeping Bags and Jackets.

Each method has its own unique advantages and disadvantages, and the choice of method typically depends on factors such as the intended use, cost, and performance requirements.

1. Calendering Finish

Calendering is a process that uses mechanical pressure to flatten and smooth the surface of the fabric. By applying heat and high pressure, it smooths the fabric’s surface, reduces fiber looseness and wear, and prevents lint formation.

Advantages:

- Enhanced surface smoothness: Calendering can make the fabric’s surface smooth and glossy, giving it a high-end appearance.

- Improved abrasion resistance: Since the surface is flattened, there is less friction, which helps reduce fiber loosening and pilling.

- Maintains softness: During the calendering process, the fabric’s softness is usually not affected, keeping it comfortable to wear.

Disadvantages:

- Potential fiber damage: Excessive calendering can cause fiber breakage or damage, affecting the fabric’s durability.

- Limited anti-pilling effectiveness: For certain fibers, especially natural fibers (such as wool, cotton, etc.), calendering is not a fully effective anti-pilling method.

- Higher cost: Calendering equipment and processes are more complex and costly compared to coating treatments.

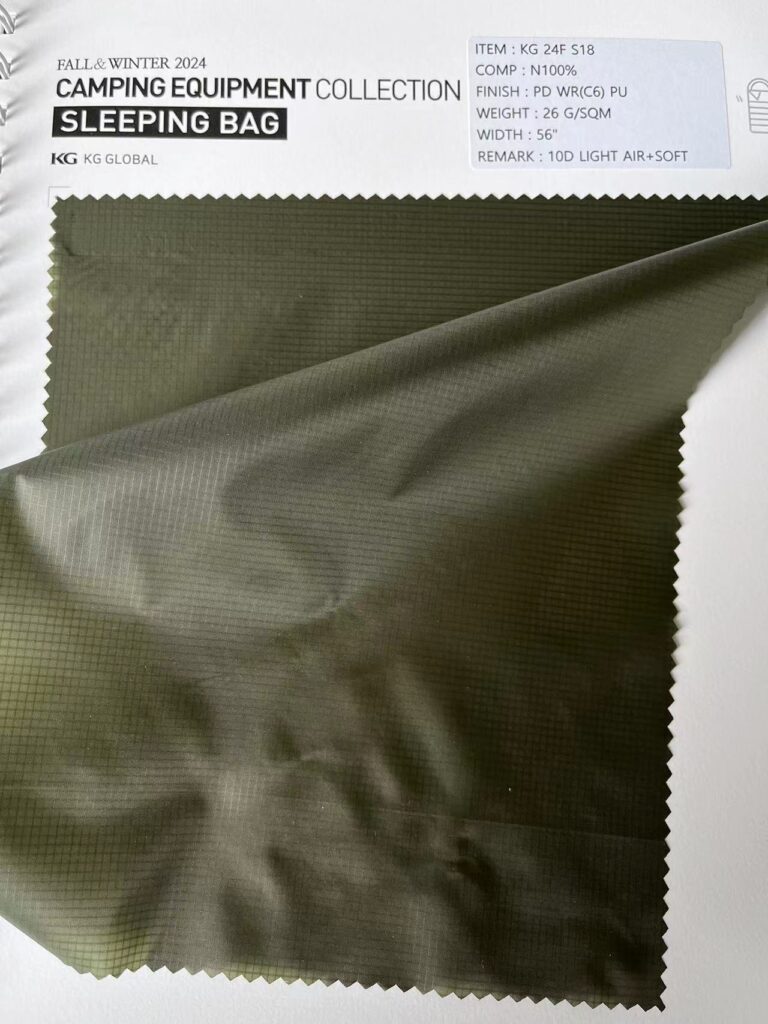

2. Coating Finish

Coating involves applying a protective layer (such as polyurethane, silicone, acrylic resins, etc.) to the fabric surface to reduce fiber looseness and prevent the formation of lint. This coating typically forms a thin film that protects the fabric surface.

Advantages:

- Effective at preventing lint: The coating forms a protective layer on the fabric’s surface, preventing fiber loosening and providing good anti-pilling effects.

- Increased durability: The coating can enhance the fabric’s durability, preventing lint formation due to friction, and extending its lifespan.

- Adaptability to various fabrics: Coating anti-pilling technology can be applied to various fibers, including both natural and synthetic fibers.

Disadvantages:

- Reduced breathability: The coating can affect the fabric’s breathability, making it less comfortable, particularly during long wear when it may feel stifling.

- Potential impact on softness: The coating may cause the fabric’s surface to become stiffer or lose its original softness, affecting the wearing experience.

- Coating degradation: Over time, the coating may degrade due to friction, washing, or other factors, causing the anti-pilling effect to weaken.

- Affects dyeing quality: Some coatings may affect the fabric’s dyeing quality, making the color appear less natural or vibrant compared to uncoated fabrics.

Summary:

- Calendering is suitable for fabrics that need to remain smooth and glossy without significantly compromising softness. It works well for certain high-end fabrics, but the anti-pilling effect may be limited.

- Coating on the other hand, is ideal for applications where a higher level of anti-pilling performance is required, especially for fabrics that need to be durable or used in environments with frequent friction. However, it may affect breathability and softness, and the durability of the coating can be an issue.